Menzel Medium High Voltage Slip Ring Motors

High Voltage Slip Ring Motors

A medium high voltage slip ring motor is an industrial motor used in a wide range of applications. This motor can be found in cement plants, pump systems, mines and in other applications with particularly high mechanical loads. They are also often used as prime movers in machinery, blower, compressor, transportation and building materials industry equipment.

Despite the fact that these motors require higher maintenance than their squirrel cage counterparts, they offer many advantages over other types of motors. Specifically, they are ideal for applications with high load inertia, such as mill drives, and operations in remote areas with weak grid conditions. This is because these motors can deliver high starting torque without using a lot of current. Additionally, they can continue to deliver high torque over a wide speed range.

These factors make them well suited to the needs of applications in the mining and cement industries. However, they are also a great choice for any application that requires high starting torque or low currents. They are also highly reliable and can be controlled and maintained by plant staff directly on-site.

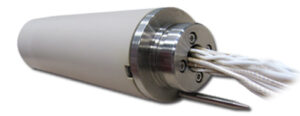

medium, high voltage slip ring motors

Menzel manufactures medium to high voltage asynchronous motors with a variety of frame sizes and output capacities. They are available with either squirrel-cage rotors or slip rings. Menzel can also provide custom designed solutions for specific applications.

Menzel Medium High Voltage Slip Ring Motors

Medium to high voltage slip ring motors are ideal for a wide range of applications, such as pumps, fans, conveyors, crushers and other general purpose machinery in the steel, mining and metal metallurgy industries. These motors can be equipped with a variety of accessories, such as cooling fan, temperature sensor and overload relay.

These motors have a compact design and are suitable for installation in small spaces. They can be mounted on the side or on the top of a machine. They can also be mounted on a flexible shaft, which makes them more versatile. They can be used for both AC and DC machines.

The main outlet box is IP54 and is generally installed on the right side of the motor (facing the motor shaft extension end). However, it can be installed on the left side according to customer requirements. The motors can be equipped with a wide variety of bearings, depending on the power and speed. The standard type of bearing is rolling bearing, but they can be upgraded to sliding bearings if required.

The YRKK series 6KV/10KV high voltage wound rotor slip ring motor is used to drive windlass, press machinery, crusher and other heavy mechanical equipment in coal, steel, mining and mechanical industries. It is also used as a prime mover in transportation, building materials and other industries. This motor has the characteristics of high efficiency, energy saving, low noise, low vibration and light weight. It is easy for installation and maintenance. It can be used as a replacement for many kinds of equipment, such as the old three-phase asynchronous motor, AC induction motor and other electric motors.