Thermal Management in HDI PCBs

Management in HDI PCBs

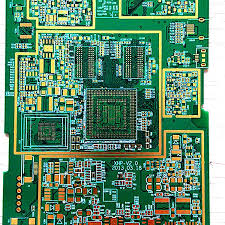

When current flows through electronic components, they produce heat. Over time, this heat can cause the PCB to overheat, leading to potential failure and safety issues. The amount of heat produced by a given device will vary, but the board material used and component placement are key factors in its ability to dissipate this heat.

To prevent overheating, designers use various techniques to improve the thermal management of hdi pcb. To do this, they must carefully select the materials for the core and surface of the PCB, as well as choose the right coatings. For example, the choice of laminate material will determine how much heat the circuit board can withstand. Likewise, the choice of finish will impact how easily it can be soldered or reworked. Common finishes include ENIG, HASL, immersion tin and gold.

The number of layers and type of via structure will also influence a board’s thermal performance. To maximize performance, the board’s copper-to-edge clearance should be within acceptable limits for the manufacturing process. Additionally, the minimum trace width and spacing should be considered.

Thermal Management in HDI PCBs

High-speed signals require a solid ground plane to provide a return path for current and reduce crosstalk. This is essential for maintaining signal integrity, especially in high-density designs where traces have narrower spaces and gaps between them. It is also important to avoid routing traces over a split plane or void, as this can lead to impedance discontinuity and degraded signal quality.

Power-consuming devices will generate a lot of heat and should be placed in locations with the best heat dissipation. These areas will typically be near the center of the board, where they can be more effectively cooled by air circulation. It is also important to distribute the power-generating components evenly across the board. Doing so will prevent hot spots from forming around specific points on the board and can help ensure that the entire circuit board is capable of dissipating the heat it produces.

In addition to the above, using a heat sink or cooling fan will increase the overall thermal performance of a high-density board. Similarly, choosing thinner boards with more surface area will allow them to dissipate heat faster than thicker ones.

The final step in ensuring optimal thermal performance is to use a qualified Printed Circuit Board (PCB) manufacturer. The ideal partner will be able to provide the shortest turnaround times and highest quality products. In addition, they should be able to offer a variety of assembly services and design tools to suit your requirements. This includes a comprehensive design rules engine and Layer Stack Manager, as well as the ability to quickly and accurately calculate impedance values. For the best results, you should also consider using a design software that is compatible with HDI technology. For example, Altium Designer offers the ability to create bare HDI circuit boards with fillets and annular rings using semiconductor class 100 clean rooms. Get started with a free trial of Altium Designer today!